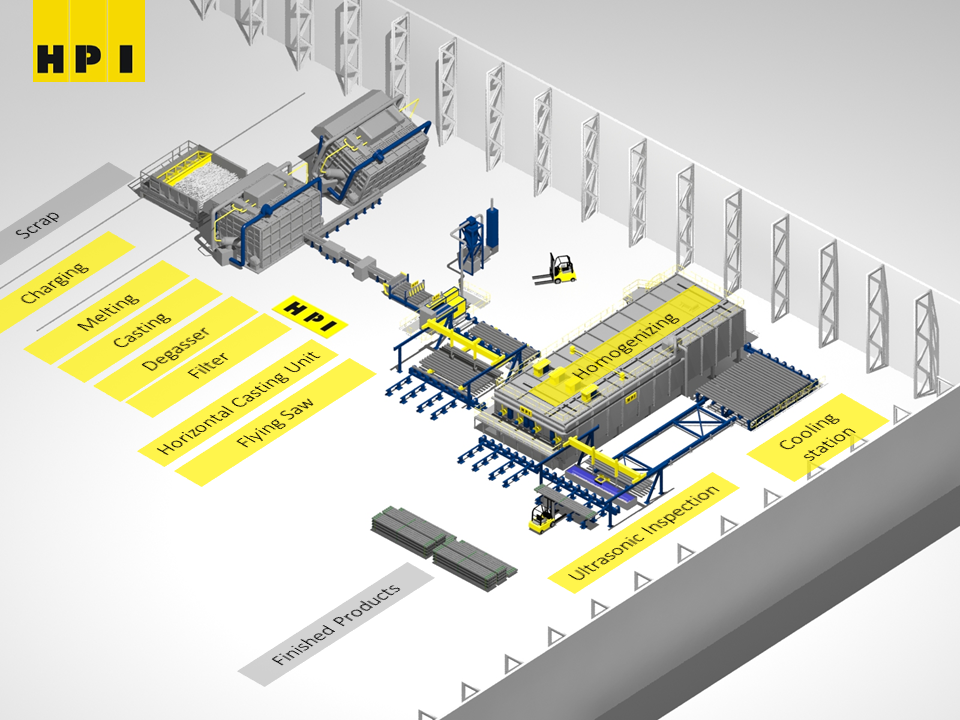

Aluminium "Flex" remelt plant

From scrap to ultrasonic inspected billets

From scrap to ultrasonic inspected billets

Aluminium "Flex" remelt plant

The HPI “Flex” remelt plant enables you to process aluminium scap into high-quality billets. Even with low quantities of scrap, a complete remelt plant of one’s own should be considered. We offer an efficient plant design, based around a horizontal casting line combined with a continuous homogenising line.

The result: inspected, ready-to-ship billets.

Plant equipment:

- Charging machine

- Melting / casting furnaces

- Metal treatment equipment

- Metal transport

- Horizontal casting machine

- Flying saw

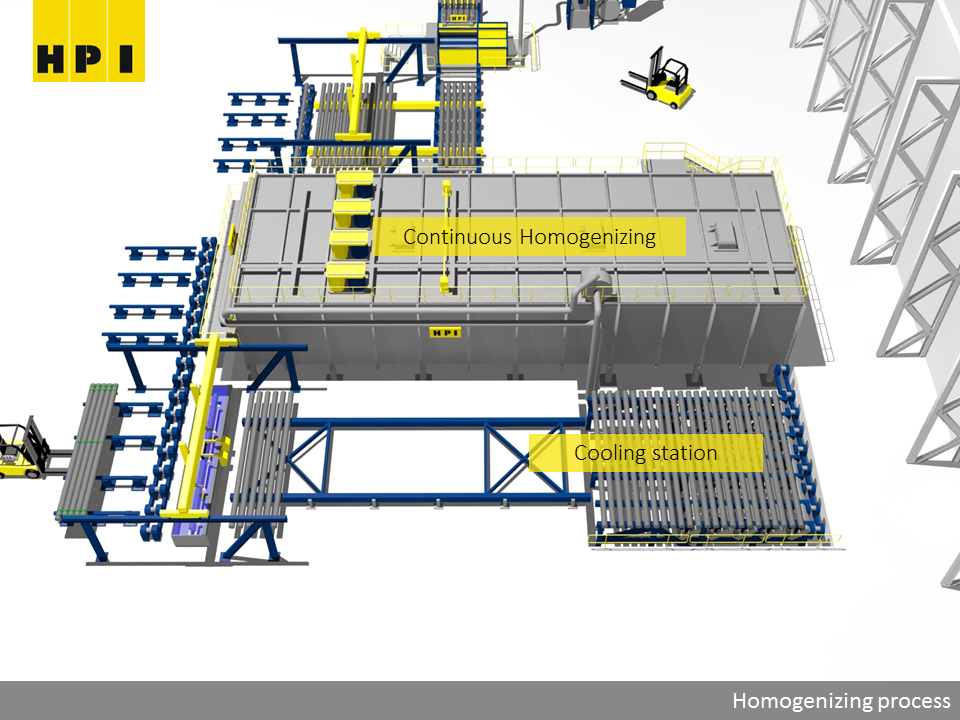

- Continuous homogenising line

- Cooling station

- Ultrasonic inspection equipment

- Marking and packing station

Features & benefits:

- Frequent change of alloy at accurate alloy composition

- Wide range of alloys

- Remelting of long scrap

- Less dross and in-house scrap (cropped ends)

- Continuous casting and sawing process

- Low operation costs

- In-house recycling: savings on freight, price fluctuations

- Automated process control with complete data acquisition

Specifications:

- Products: extrusion and forging billets, bus bars, slabs & ingots

- Capacity from 3,000 to 30,000 tons / year