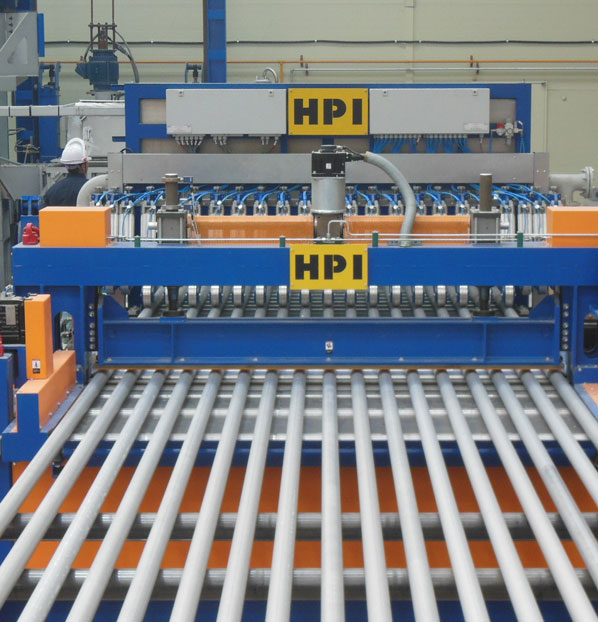

Horizontal casting lines

From molten metal to semi-finished products

From molten metal to semi-finished products

Horizontal casting lines

Our horizontal casting lines transform liquid metal into high-quality prematerial with precision and efficiency. Thanks to state-of-the-art mold technology and decades of manufacturing expertise, they enable the production of a wide range of products – from extrusion and forging billets to cast plates, busbars, T-bars, and ingots.

With a broad alloy range, continuous casting and sawing processes, and fully automated process control, HPI systems deliver maximum product quality, low operating costs, and outstanding efficiency with annual capacities from 3,000 to 50,000 tons.

A variety of products at one and the same machine:

Specifications:

- Production capacity between 3,000 and 50,000 t/year

Features & benefits:

- Mould technology and producer know-how

- Wide range of alloys

- Continuous casting and sawing process

- Automatic sawing system

- Low operating costs

- Reduced in-house scrap (crop ends)

- Automated casting process control with complete data acquisition